coal mill

Coal Mill - an overview ScienceDirect Topics

Coal mills or pulverizers play a very essential part in the coal-fired power production system. Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion. Mills can be a bottleneck for the power generation process.2017年8月12日 Loesche coal grinding mills are distinguished by other characte- ristics that improve efficiency, safety and environmental protec- tion, from the standard version to top-of-the-range installations:LOESCHE-MILLS2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants fired by pulverized coal. The model is relatively simple, yet it Derivation and validation of a coal mill model for control

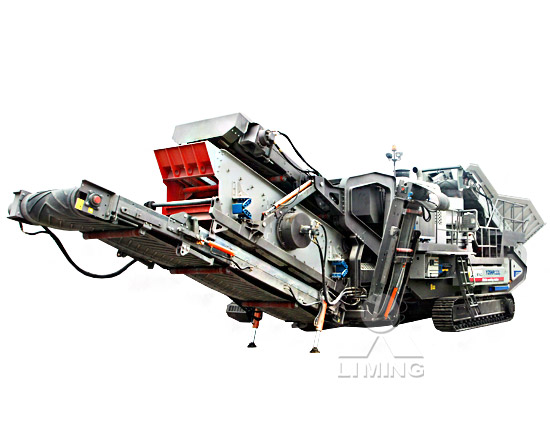

Coal Mill in Cement Plant Vertical Roller Mill Air-Swept Ball Mill

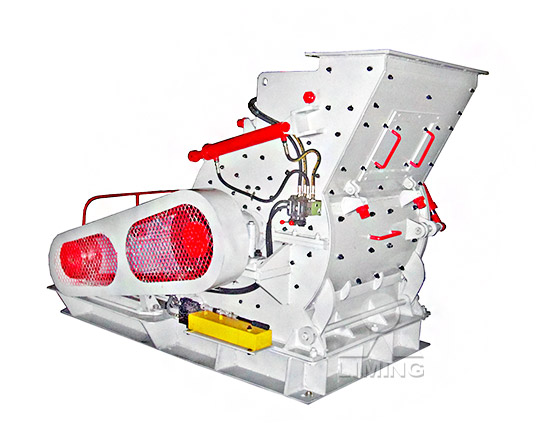

A coal mill is also called a coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills.2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency.An investigation of performance characteristics and 2015年8月1日 Coal mills or pulverizers play a very essential part in the coal-fired power production system. Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion. Mills can be a bottleneck for the power generation process.Review of control and fault diagnosis methods applied to coal mills ...

Coal Mill_北方重工

Our company has comprehensively established own product series of high , medium and low speed coal mills, with the production capacity of hundreds of mills each year.2019年8月27日 Abstract. Abstract: The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studied. The flow field adjacent to two neighboring impeller blades was measured using the particle image velocimetry technique.Classification performance of model coal mill classifiers with ...2016年1月18日 This paper presents the shortcomings of traditional PID method in coal mill control, such as multivariable coupling, nonlinearity and large-time delay, and give a new method to solve the problems. Firstly, the principles of coal mill is presented, and a coal mill model is established.The Inferential predictive control method of coal mill IEEE ...

Coal Mill - an overview ScienceDirect Topics

Coal mills or pulverizers play a very essential part in the coal-fired power production system. Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion. Mills can be a bottleneck for the power generation process.2017年8月12日 Loesche coal grinding mills are distinguished by other characte- ristics that improve efficiency, safety and environmental protec- tion, from the standard version to top-of-the-range installations:LOESCHE-MILLS2012年5月1日 The paper presents development and validation of a coal mill model to be used for improved mill control, which may lead to a better load following capability of power plants fired by pulverized coal. The model is relatively simple, yet it Derivation and validation of a coal mill model for control

Coal Mill in Cement Plant Vertical Roller Mill Air-Swept Ball Mill

A coal mill is also called a coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills.2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coal-fired power plant. In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency.An investigation of performance characteristics and 2015年8月1日 Coal mills or pulverizers play a very essential part in the coal-fired power production system. Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion. Mills can be a bottleneck for the power generation process.Review of control and fault diagnosis methods applied to coal mills ...

Coal Mill_北方重工

Our company has comprehensively established own product series of high , medium and low speed coal mills, with the production capacity of hundreds of mills each year.2019年8月27日 Abstract. Abstract: The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studied. The flow field adjacent to two neighboring impeller blades was measured using the particle image velocimetry technique.Classification performance of model coal mill classifiers with ...2016年1月18日 This paper presents the shortcomings of traditional PID method in coal mill control, such as multivariable coupling, nonlinearity and large-time delay, and give a new method to solve the problems. Firstly, the principles of coal mill is presented, and a coal mill model is established.The Inferential predictive control method of coal mill IEEE ...